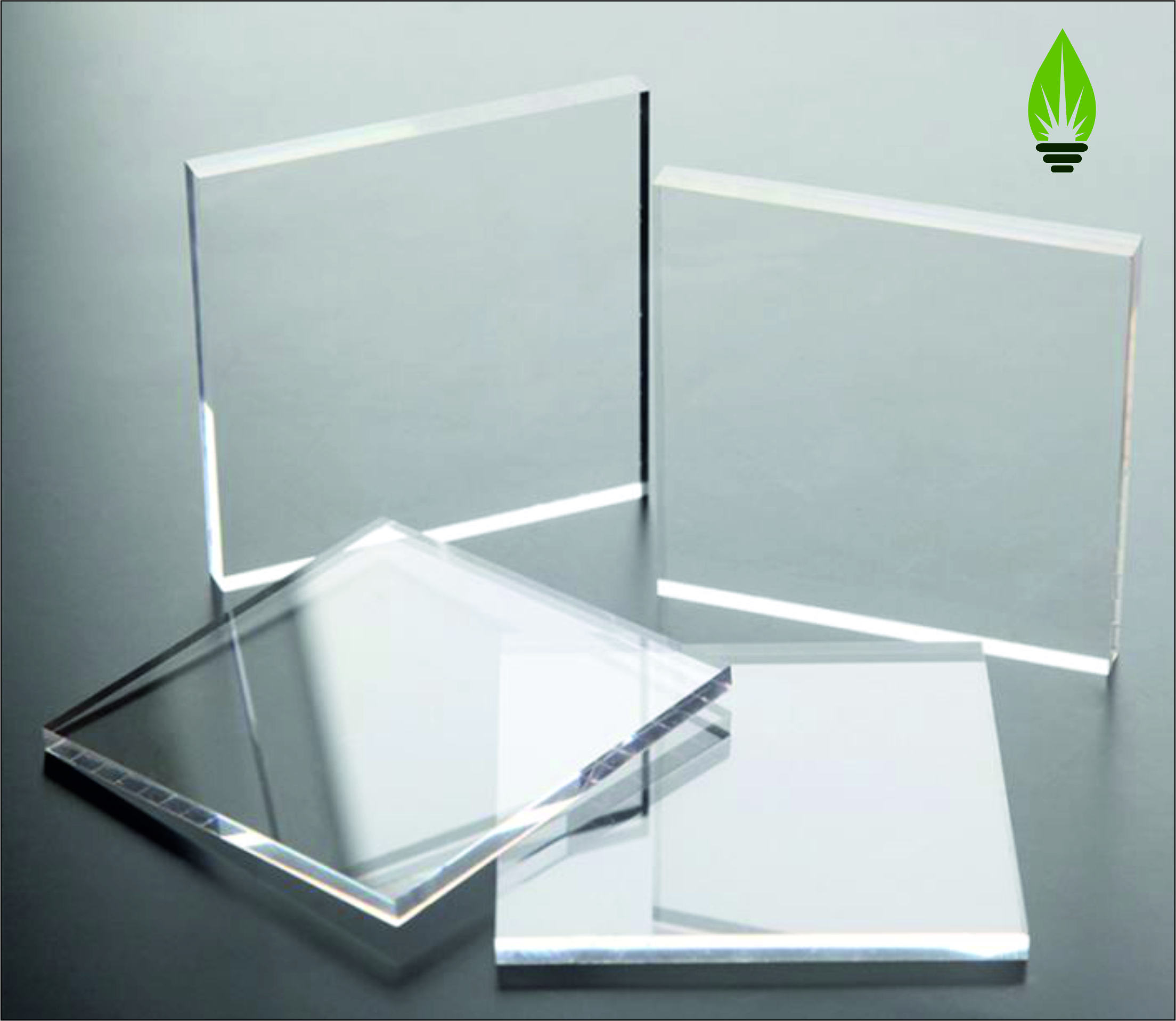

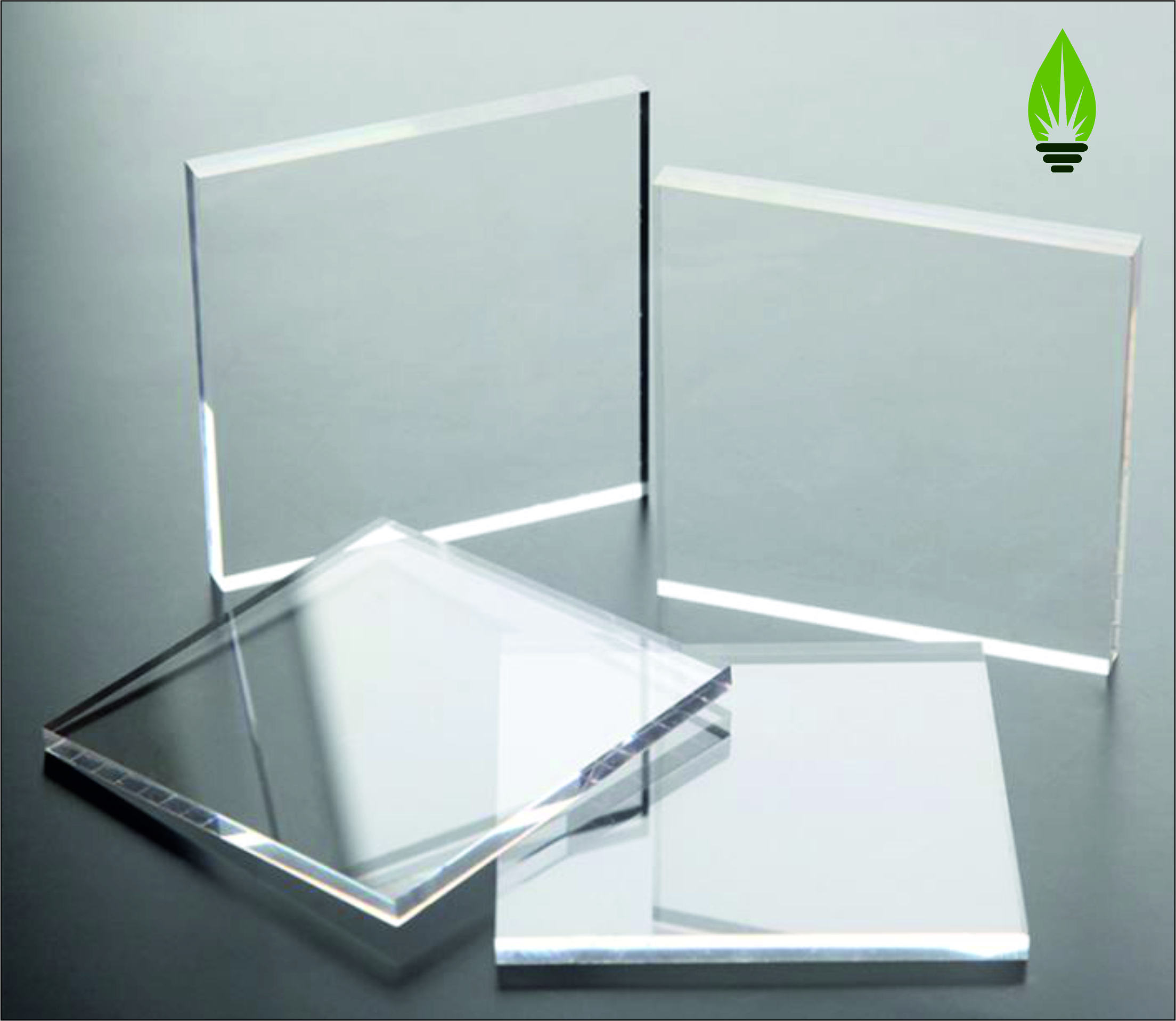

Clear Extruded Acrylic sheet

5 Review(s)

From £1.5 inc VAT In stock

Clear Extruded acrylic is a high quality and versatile plastic sheet material offering high levels of strength and clarity. The sheets maintain their optical properties for several years and for suitable for industries such as construction and signage and other various uses. These are easy to work and make it an excellent replacement for glass. The sheets weigh 1.2kg/sqmt/mm whereas glass weigh 2.5kg/sqmt/mm; hence, these sheets are lighter than glass by 50%

Key features:

- Excellent optical clarity

- Roof Glazing

- Safety Glazing

- Easy Moulded

- Good Mechanical Strength

- High gloss finish

- Hard wearing

- Resistant to Hard Weather

- Easy to work with/fabricate

- Lightweight

- High Impact Strength.

Typical applications:

- Glazing

- Signage

- Furniture

- Model fabrication and display

- Retail display

- Point of sale

- Point of purchase

Optical clarity

Excellent high level of light transmission, Excellent Transparency allowing 92% of all visible light through the material creating an unparalleled crystal clear finish. Refractive Index 1,489. Due to crystal clear finish these material are also used for glazing purposes.

Hard wearing

Cast acrylic is one of the hardest thermoplastic sheet materials, with ball pressure hardness of 185 MPa, Tensile strength at breakage 78 MPa. This gives a good mechanical strength its attractive aesthetics remain for longer than other plastic sheet materials.

Light weight

The sheets weigh 1.2kg/sqmt/mm whereas glass weigh 2.5kg/sqmt/mm; hence, these sheets are lighter than glass by 50% While offering higher levels of clarity than glass, clear cast acrylic weighs half as much as an equivalent glass panel making fabrication, installation and transportation a far more attractive proposition.

High gloss finish and easy to clean

Its high gloss finish is not only very attractive but also more practically very easy to clean.

Resistant to harsh weather

With excellent resistance to the elements, cast acrylic performs well outside. No significant changes in appearance are expected over 10 years, Rockwell hardness on M/R scale is 92, and VICAT softening temperature is 107 degree Celsius.